product introduction

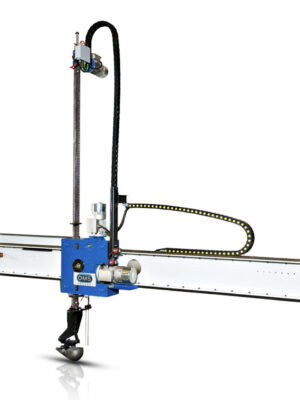

SIST 5 GR is indicated for the addition of granular and powdered deoxidising, modifying and refining products. The hopper can hold up to 25 kg of flux and has a level indicator that signals a lack of product. A pipe conveys the product to the vortex created by a graphite shaft and rotor. An automatic blade-rotation system creates a vortex that is only needed when dosing the flux. The degassing treatment takes place in the absence of the vortex with the descent of the blade into the bath.

The electrical control panel, with PLC, allows:

– Operating in manual, automatic or maintenance mode

– Enabling and disabling flux dosing

– Selecting from 10 cycles that manage:

- Regulation of the total cycle time

- Dosing delays and product quantities

- The machine’s safety devices

There are no reviews yet.